Let’s discuss the question: how to true a harley crankshaft. We summarize all relevant answers in section Q&A of website Linksofstrathaven.com in category: Blog Finance. See more related questions in the comments below.

Can a crankshaft be rebuilt?

Crankshaft rebuilding can be done yourself, though you need to understand how it works and why it is important to the engine. In most instances, rebuilding the parts of the engine is much less expensive than replacing it and is frequently done when restoring or customizing a car.

How do you straighten a motorcycle crankshaft?

RE: best way to straighten a slightly bent crankshaft

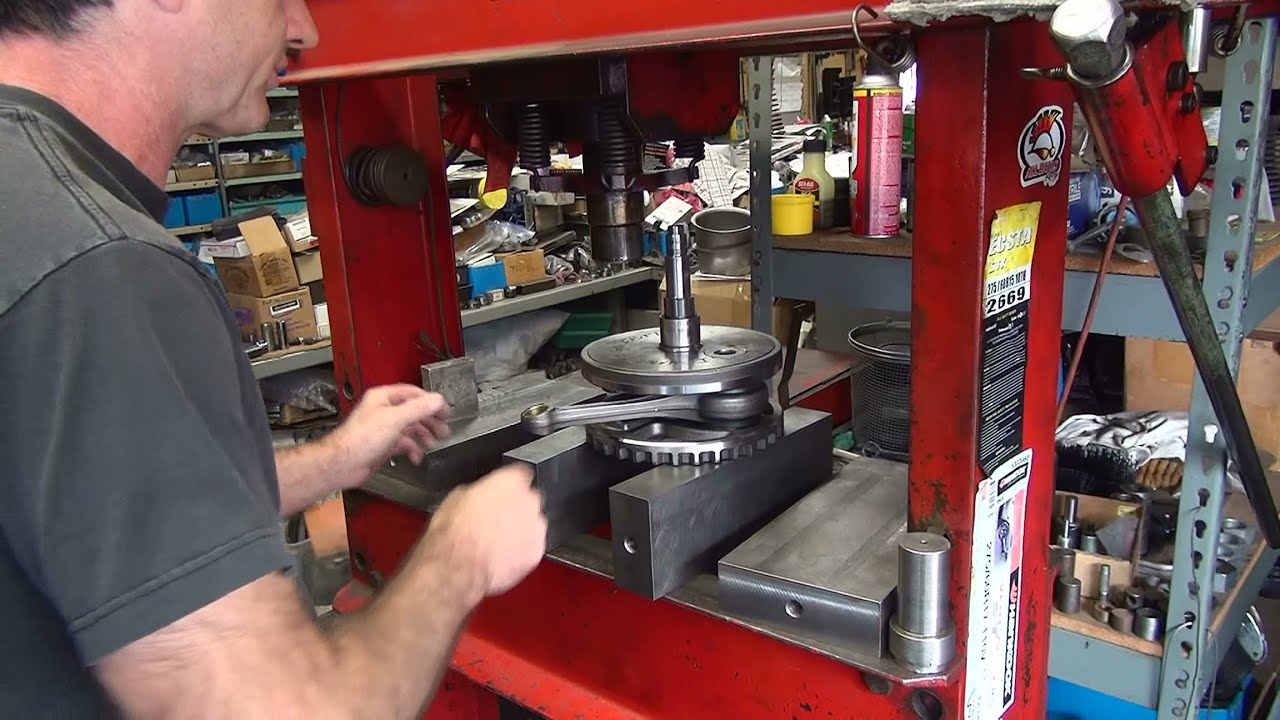

The basic method is to remove the crankshaft from the engine. Then you determine where the bent spot is. You then can use a press to apply pressure to the bent spot a little, then repeat the check and repeat the pressure as needed.

CRANKSHAFT TRUING MADE EASY | How To True Two Stroke Crank | 2 STROKE TUNING

Images related to the topicCRANKSHAFT TRUING MADE EASY | How To True Two Stroke Crank | 2 STROKE TUNING

How much play should a crankshaft have?

Generally speaking, keeping the thrust clearance at 0.004 to 0.005-inch is appropriate but it is best to check the recommended clearance. For example, late model engines prefer a slightly tighter clearance to minimize travel of the crank sensor reluctor wheel.

How do you tell if a crank needs to be turned?

Generally speaking, if the crank shows less than 0.001-inch runout, it’s probably fine. If the crank shows more than 0.001-inch runout, it needs to be either straightened or replaced. Crank straightening is a precision task that should only be handled by a skilled specialist.

Can you weld a crankshaft?

When welding a crankshaft journal, the journal is preground to remove electrolysis. All gears are removed, then it is welded in a submerge arc processor to build up the journal. The crankshaft is then placed in an oven to stress relieve the crank.

Rowe style crankshaft truing stand jig true any Harley Indian Japanese cranks check runout ovality

Images related to the topicRowe style crankshaft truing stand jig true any Harley Indian Japanese cranks check runout ovality

Does polishing crank remove material?

You cannot polish that much material off. You must grind it. It can be done by a skilled grinder – I guarantee that because I have it done every week or two.

What is the purpose of crankshaft deflection?

Crankshaft deflections are measured to detect the misalignment of main bearings. The misalignment occurs due to bearing wear or deflection of the crankshaft.

Can a crankshaft be straightened?

If so, then it is often possible to straighten the crankshaft in-situ, without removing it from the crankcase. This process is known as “peening” and is a cold process, whereby a small force is applied to the correct places repeatedly to bring the shaft back to its original straightness.

#101 how not to straighten welded flywheel 2011 twin cam crankshaft truing harley by tatro machine

Images related to the topic#101 how not to straighten welded flywheel 2011 twin cam crankshaft truing harley by tatro machine

How do I know if my crankshaft is bent?

- Excessive Vibration. Even if your crankshaft is just a tiny bit bent, you will notice some pretty serious vibration. …

- Strange Noises When Running. …

- Your Cut Looks Uneven. …

- Trouble Starting Your Mower/Stalling Issues. …

- Disconnect Spark Plug + Then Remove It. …

- Tilt Your Mower.

Can I change pistons without balancing?

But can you change pistons without balancing? The answer to this question is yes, it is possible to change pistons without balancing. In other words, if you want to replace the old piston with a new one, there is no need for balance for the accessories.

Related searches

- how to balance a harley crankshaft

- how to make crankshaft truing stand

- harley twin cam crankshaft problems

- harley flywheel rebuilding

- how to true a motorcycle crankshaft

- harley davidson crankshaft

- harley-davidson crankshaft

- harley m8 crankshaft

- welding harley crankshaft

- harley crankshaft rebuilding

- how to crank a harley davidson

Information related to the topic how to true a harley crankshaft

Here are the search results of the thread how to true a harley crankshaft from Bing. You can read more if you want.

You have just come across an article on the topic how to true a harley crankshaft. If you found this article useful, please share it. Thank you very much.