What is the best tool for polishing stones?

Think of a Dremel as your go-to tool for giving your gemstones that extra shine. It’s like a mini power tool that lets you get into tight spots and work on intricate details. You can use different burrs with varying grit levels to achieve the desired finish. For example, a coarse burr is great for removing rough edges, while a fine burr will help you achieve a smooth, polished surface.

When using a Dremel to polish stones, it’s important to use light pressure and let the tool do the work. You’ll also want to use a lubricant, such as water or polishing compound, to help prevent the stone from overheating and to ensure a smooth finish. With a little practice, you’ll be able to polish your stones to a beautiful, professional-looking finish.

Can a Dremel be used on stone?

You can use Dremel tools to work on stone in a variety of ways. For example, you can use them to shape, smooth, and cleanstone. You can also use Dremel tools to removestone from surfaces, such as when removing excess stone from a countertop. When working with stone, it’s essential to use the right type of Dremel tool and attachment. A diamond-tipped bit is best for stone, as it’s strong and durable enough to cut through the hard material. It’s important to wear protective gear, such as safety glasses and a dust mask, when using Dremel tools to work with stone. This will help to protect you from dust and debris.

Remember, stone is a hard material, so it’s important to be careful when using a Dremel tool. Start with a lowspeed and increase it gradually as needed. Be sure to use a firmgrip on the tool and to avoidapplying too much pressure.

It’s important to note that Dremel tools are not a substitute for professionalstoneworking tools. If you’re doing a majorproject involving stone, it’s best to consult with a professional. However, for smallerprojects, a Dremel tool can be a greattool for working with stone.

How do you polish raw stones at home?

You can easily polish stones at home using simple materials. One of the easiest methods is using polishing powder and a denim cloth. Simply apply a small amount of powder to the cloth and gently rub it over the stone’s surface. This method is great for giving your stones a gentle shine.

Another option is using baking soda. While baking soda is primarily used for baking, it can also be used as a gentle abrasive for polishing stones. Simply mix a small amount of baking soda with water to create a paste. Apply the paste to the stone and rub it gently with a soft cloth. Rinse the stone with water and dry it thoroughly.

It’s important to note that these methods are best for polishing softer stones like agate, jasper, and turquoise. For harder stones like quartz, amethyst, and diamond, you’ll need to use a more abrasive method like sandpaper or tumbling with a rock tumbler.

Here’s a more detailed explanation of how to polish stones using denim and polishing powder:

1. Choose your stone: Select a stone that you want to polish. Make sure the stone is clean and free of any dirt or debris.

2. Get your materials: You’ll need a denim cloth and polishing powder. Polishing powder can be purchased online or at craft stores.

3. Prepare the denim: Fold the denim cloth into a small square.

4. Apply the powder: Sprinkle a small amount of polishing powder onto the denim cloth.

5. Polish the stone: Rub the denim cloth over the stone in a circular motion. Apply gentle pressure and avoid pressing too hard.

6. Rinse and dry: After polishing, rinse the stone with water and dry it thoroughly.

Remember, patience is key when polishing stones! It may take some time to achieve the desired shine, so don’t get discouraged if your stone doesn’t look perfect after the first attempt. Keep polishing, and you’ll eventually get the results you want.

How do I polish rocks with a Dremel tool?

Once you’ve reached a smooth finish with the sandpaper, it’s time to add the finishing touches.Attach a polishing wheel to your Dremel and apply a polishing compound to the rock. The polishing wheel will buff the rock, giving it a brilliant shine. You’ll have a rock collection that will impress all your friends!

Here’s a more detailed guide on how to use sandpaper and polishing wheels with your Dremel:

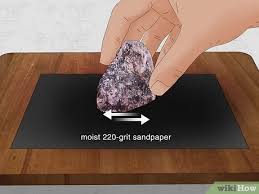

Sandpaper: You’ll need sandpaper in various grits. Start with a coarse grit like 80 grit to remove any rough edges or imperfections. Then, progress to finer grits like 120, 220, 400, and 600. This process gradually smoothes out the rock’s surface.

Polishing wheel: The polishing wheel attachment is crucial for that final gleam. These wheels come in various materials, like felt or leather. They’re designed to apply polishing compound to the rock, creating a shiny, smooth surface.

Remember:

Take your time and be patient! Polishing rocks can be a rewarding process, but it’s important to go slow and steady.

Wear safety goggles to protect your eyes from flying debris.

Use a dust mask to avoid inhaling any rock dust.

Enjoy the process and the amazing results!

How do jewelers polish stones?

The tumbling process is a gentle and effective way to polish stones. It allows jewelers to create smooth, even surfaces on stones of all shapes and sizes. This process is often used to polish stones that have been cut into specific shapes, such as round, oval, or emerald cuts.

Think of it like sanding wood. You start with a rough sandpaper and work your way down to finer grits until you have a smooth finish. The same principle applies to polishing stones.

The tumbling process uses a rotating drum filled with stones and abrasive. As the drum rotates, the stones rub against each other and the abrasive, gradually smoothing and polishing the surfaces. The abrasive is usually silicon carbide, which is a hard and durable material. It’s available in different grades, from coarse to fine. The jeweler chooses the appropriate grade of abrasive depending on the type of stone and the desired finish.

The tumbling process can be used to polish a variety of stones, including diamonds, sapphires, rubies, and emeralds. It’s a key step in the jewelry-making process, ensuring that the stones are beautiful and ready to be set into jewelry.

Can I drill stone with a Dremel?

The stone you want to drill a hole in.

A Dremel, Foredom, or similar rotary tool. A flex-shaft attachment is super helpful, but not absolutely necessary.

A container that’s deep enough to hold the stone but not so deep that you can’t easily hold it in place.

Let’s talk about those tools! You’ll want to make sure you’re using the right Dremel bit for the job. Diamond-coated bits are best for drilling into stone. These bits are specifically designed to cut through hard materials like granite, marble, and even concrete. They come in different sizes and shapes, so you can choose the right one for the size and type of hole you need.

Another important aspect is to work safely. Drilling into stone creates dust, so you’ll want to wear a dust mask to protect yourself from inhaling it. Safety glasses are also important to shield your eyes from flying debris. Also, you’ll want to make sure the stone you’re drilling into is securely held in place. This will prevent the stone from moving while you’re drilling and help you avoid accidents.

Once you’ve got your tools and materials gathered, you’re ready to start drilling. Go slow and steady! Stone is pretty tough stuff, so don’t try to force the bit. Let the Dremel do the work, and you’ll have a nice clean hole in no time.

What are stone Dremel bits used for?

Let’s break down what all that means. Sharpening with a Dremel stone means making a dull edge sharp again. This is useful for things like knives, chisels, and even scissors. Deburring is the process of removing sharp edges or burrs from metal. This helps to prevent injuries and makes the surface smoother. General purpose grinding can be used for a variety of tasks, from shaping metal to smoothing out rough surfaces.

Think of these Dremel bits as your go-to tools for making those small-scale adjustments that can make a big difference. They’re perfect for working on intricate details, removing imperfections, and giving those DIY projects a professional finish. Whether you’re a seasoned pro or just starting out, these bits are a valuable addition to any toolbox!

See more here: Can A Dremel Be Used On Stone? | How To Polish Stones With A Dremel

How to Polish stones with a Dremel?

First things first, clean your rocks. Give them a good scrub to get rid of any dirt or debris. This will help you get a better polish.

Next, secure your stone. You want to make sure it’s held steady while you work. You can use a vise or a clamp. This will help you keep the stone in place and make your job a lot easier.

Remember, choosing the right bit for your Dremel is important. You’ll need different bits for different types of stones. And water is your friend! It helps keep things cool and prevents the stone from overheating.

With a little practice, you’ll be a stone polishing pro in no time. It’s really satisfying to see a rough stone transformed into a smooth, shiny gem!

Here’s how to choose the right Dremel bit for polishing:

Diamond bits: These are your go-to for the first stage of polishing. They’re tough and will help you smooth out the rough edges of your stone. Look for diamond bits with different grit levels, starting with a coarser grit and working your way to a finer grit.

Felt bits: Once your stone is relatively smooth, you can move on to felt bits. They’re great for adding a shine to your stone. Felt bits come in a variety of colors and they’re coated with polishing compounds, like alumina oxide, cerium oxide, or tin oxide.

Polishing compounds: You can also use polishing compounds separately. These compounds come in different grit sizes too. Apply the compound to your felt bit and start polishing.

Remember: As you work, be sure to check your progress frequently. If you see any scratches or imperfections, you can go back to a coarser grit bit to fix them.

With a little patience and practice, you can achieve a beautiful, polished finish on your stones.

How do you Polish rocks on a Dremel?

First, choose the rock you want to polish. Secure it firmly in a vice clamp. This will keep the rock steady while you work on it. Then, start grinding the rock down with progressively finer sandpaper. You can use a sanding attachment on your Dremel for this.

Once you’ve reached the desired smoothness with sandpaper, you can move on to the polishing stage. Attach a polishing wheel to your Dremel and apply a polishing compound. This will give your rocks a brilliant shine.

Here’s a more detailed breakdown of the process:

1. Preparing the Rock:

Selection: Choose a rock that is relatively smooth and free of cracks or imperfections. Rocks with a rough surface will require more time to polish.

Cleaning: Wash the rock with soap and water to remove any dirt or debris.

Securing: Secure the rock in a vice clamp. Make sure the rock is held securely so it doesn’t move while you’re working on it.

2. Grinding:

Sandpaper: Use a series of progressively finer grit sandpaper, starting with a coarse grit and working your way down to a fine grit.

Technique: Gently apply pressure as you grind the rock. Move the Dremel in a circular motion, covering the entire surface of the rock.

Inspection: Check your progress regularly and adjust the grit of your sandpaper as needed.

3. Polishing:

Polishing Wheel: Attach a polishing wheel to your Dremel. There are various types of polishing wheels available, such as felt wheels, buffing wheels, and leather wheels.

Polishing Compound: Apply a polishing compound to the polishing wheel. Polishing compounds are available in a variety of grades, with finer grades producing a higher shine.

Technique: Use a light touch and apply even pressure to the rock as you polish it. Move the Dremel in a circular motion, covering the entire surface of the rock.

Final Touches: Once you’re satisfied with the shine, you can use a polishing cloth to buff out any remaining imperfections.

By following these steps, you can transform your rocks into beautiful, polished specimens. You can even experiment with different polishing compounds and techniques to create unique and stunning finishes.

Can you use a Dremel rotary tool to Polish rocks?

First, you’ll need the right tools:

Dremel Rotary Tool: This is the workhorse of your rock-polishing setup. You’ll want to make sure you get one that has a good range of speeds and comes with a variety of attachments.

Polishing Wheels: These are specifically designed for polishing rocks and come in various grits.

Diamond Polishing Paste: This paste is used in conjunction with polishing wheels to give your rocks a high-gloss finish. It’s available in different grades of coarseness.

Safety Glasses: Always protect your eyes when working with a Dremel, as it can create flying debris.

Now, let’s talk about the process:

1. Prepare your Rocks: Clean your rocks thoroughly to remove any dirt or debris. You can use a brush, soapy water, and even a small toothbrush to make sure they’re clean.

2. Start with a Coarse Grit: Begin with a coarse-grit polishing wheel and diamond paste. This will remove the rough edges and imperfections of your rock.

3. Work your Way Up: As your rock starts to smooth out, switch to a finer-grit polishing wheel and paste. The finer the grit, the smoother and shinier your rock will become.

4. Final Polishing: Once you’ve achieved a smooth finish, you can use a buffing wheel with a polishing compound to give your rock that final, high-gloss shine.

A Few Tips:

Use Light Pressure: Don’t press too hard on the rock as you polish. Let the Dremel do the work.

Take Breaks: If you’re working on a large rock, it’s a good idea to take breaks to prevent the Dremel from overheating.

Be Patient: Polishing rocks takes time and patience. Don’t get discouraged if your first few attempts don’t turn out perfectly. Practice makes perfect!

Beyond the Basics:

You can get even more creative with your rock polishing by using different techniques. For example, you can create unique patterns on your rocks by using a Dremel with a carving attachment. You can even use different colored diamond paste to create stunning effects.

With a little practice and some creativity, you’ll be turning ordinary rocks into beautiful, polished gems in no time!

What should you wear when polishing rocks with a Dremel tool?

Protective eyewear will shield your eyes from flying debris, especially when using the Dremel’s higher speeds. Think about it: those little bits of rock can be like tiny projectiles! Facemasks are essential to prevent inhaling the fine dust produced while polishing. This dust can irritate your lungs and cause respiratory problems. Work gloves provide a firm grip on the tool and protect your hands from cuts, abrasions, and burns. You’ll be surprised how hot the tool can get!

You’re probably wondering, “What kind of facemask should I use?” For polishing rocks, a dust mask is a great choice. This type of mask filters out fine particles, protecting you from the rock dust. You can also use a respirator, which offers even greater protection. When choosing a respirator, look for one with a HEPA filter. This type of filter removes at least 99.97% of airborne particles, including the microscopic rock dust.

It’s important to make sure your safety gear fits snugly and comfortably. You want it to stay in place while you’re working, and you don’t want it to restrict your movements. With proper safety gear, you can polish rocks with confidence and enjoy the process!

See more new information: linksofstrathaven.com

How To Polish Stones With A Dremel | What Is The Best Tool For Polishing Stones?

Hey there, rock hounds! You’ve got a cool collection of rocks, maybe some tumbled stones, and you’re itching to take them to the next level of shine. You’ve heard about Dremel tools and how awesome they are for polishing, but you’re not sure where to start. Don’t worry, I’ve got you covered!

In this guide, we’ll go over everything you need to know about polishing stones with a Dremel, from choosing the right attachments to getting a professional-looking finish. We’ll cover the basics of stone polishing, safety tips, and common mistakes to avoid. So, grab your Dremel, gather your rocks, and let’s get started!

Understanding the Process

Polishing stones with a Dremel isn’t about just rubbing them with a cloth. It’s a multi-step process that involves gradually refining the stone’s surface until it achieves a mirror-like shine. Here’s a breakdown of the stages:

1. Rough Grinding: This step removes any rough edges, imperfections, and any unwanted material from the stone’s surface.

2. Fine Grinding: Here, we start to refine the surface by using progressively finer grits, smoothing out the rough edges and preparing the stone for the final polishing step.

3. Polishing: The final stage involves using polishing compounds and felt attachments to achieve a high-gloss, mirror-like finish.

The Key: The Dremel tool allows you to control the pressure and speed of the grinding and polishing process, making it ideal for achieving a precise and polished finish on your stones.

Essential Tools and Materials

Before you dive into polishing, gather the necessary tools and materials:

Dremel Tool: This is the star of the show. A Dremel tool is a versatile power tool with a variety of attachments for various tasks, including grinding, sanding, and polishing.

Grinding Attachments: These attachments are used for the initial rough grinding and shaping of the stone. We’ll discuss specific types later.

Sanding Bands: Sanding bands come in various grit sizes and are used for finer grinding, smoothing out the stone’s surface after the initial rough grinding.

Polishing Compounds: These compounds come in different levels of abrasiveness and are used to achieve a high-gloss finish.

Felt Polishing Wheels: These wheels are used in combination with polishing compounds to create a smooth and shiny surface.

Water: Used for keeping the stone and attachments cool and preventing overheating.

Protective Gear: This includes safety goggles, gloves, and a dust mask to protect yourself from dust and debris.

Choosing the Right Dremel Attachments

Grinding: For rough grinding, you’ll need coarse grinding attachments like diamond grinding wheels or carbide burrs. These are tough and can handle the initial shaping and smoothing.

Finer Grinding: Once the initial grinding is done, switch to sanding bands. They come in various grits, ranging from coarse to fine. Start with a coarser grit to smooth out the surface, then gradually move to finer grits to achieve a smooth and even finish.

Polishing: For polishing, felt polishing wheels are your go-to. These are usually available in various sizes and shapes. Remember, polishing requires a gentle touch to avoid damaging the stone’s surface.

The Steps to Polishing Stones with a Dremel

Now, let’s get our hands dirty! Here are the steps for polishing stones with a Dremel:

1. Prepare Your Workspace: Choose a well-ventilated area with a flat surface. This will ensure you have ample space for your tools and stones.

2. Clean Your Stones: Before starting, clean your stones thoroughly using soapy water to remove any dirt or debris that might interfere with the polishing process.

3. Secure the Stone: Use a vice or clamp to hold the stone securely. This will allow you to work on the stone safely and effectively without it moving around.

4. Rough Grinding: Attach a diamond grinding wheel or carbide burr to your Dremel. Gently guide the grinding attachment across the stone’s surface, removing any rough edges and imperfections.

5. Fine Grinding: Switch to a sanding band with a coarser grit. Work the band across the stone’s surface, smoothing out any remaining roughness from the rough grinding stage. As you work, gradually move to finer grit sanding bands to achieve a progressively smoother finish.

6. Polishing: Attach a felt polishing wheel to your Dremel. Apply a polishing compound to the wheel and gently work it across the stone’s surface. Repeat this process with different polishing compounds, moving from coarser to finer grades to achieve a high-gloss finish.

Remember: Keep the stone wet with water while grinding and polishing to prevent overheating and damage to the stone and your Dremel.

Important Tips and Considerations

Stone Type: Different stones require different polishing techniques. For example, soft stones like turquoise and malachite may require gentler polishing methods and lower Dremel speeds. Harder stones like quartz and agate can handle more aggressive grinding and polishing techniques.

Dremel Speed: Adjust the Dremel’s speed based on the stone’s hardness and the grinding or polishing stage. Start with lower speeds and gradually increase them as needed.

Pressure: Apply gentle pressure when grinding and polishing. Too much pressure can cause damage to the stone or the Dremel attachment.

Cool Down: Regularly stop grinding and polishing to allow the stone and attachments to cool down to prevent overheating.

Common Mistakes to Avoid

Here are some common mistakes to avoid when polishing stones with a Dremel:

Using the Wrong Attachments: Selecting the appropriate grinding and polishing attachments for your stone’s hardness and the stage of polishing is crucial.

Applying Too Much Pressure: Too much pressure can cause damage to the stone’s surface, leading to uneven grinding or polishing.

Overheating: Allowing the stone or Dremel attachments to overheat can damage them. Always work in short bursts with regular cooling breaks.

Not Cleaning Regularly: Cleaning your Dremel and attachments regularly will prevent debris and dust from building up, which can affect the quality of your polish.

FAQs

Can I polish stones without a Dremel?

Yes, you can! Traditional methods like tumbling and hand polishing are good alternatives.

What types of stones can I polish with a Dremel?

Many types of stones can be polished with a Dremel, including agate, jasper, quartz, amethyst, turquoise, and many others.

How long does it take to polish a stone with a Dremel?

The polishing time varies depending on the size and hardness of the stone. It can take anywhere from a few minutes to a few hours to achieve a professional-looking finish.

Is it safe to polish stones with a Dremel?

Yes, it’s safe as long as you take proper precautions, wear protective gear, and follow the instructions carefully.

What are some tips for getting a professional-looking polish?

* Use high-quality polishing compounds to achieve a mirror-like shine.

Work in small sections to ensure even polishing.

Take your time and be patient. Polishing is a process that takes practice and attention to detail.

I’m having trouble achieving a smooth finish. What can I do?

Ensure you’re using the right grits for each stage and that you’re applying gentle pressure. Check your Dremel’s speed and make sure it’s appropriate for the task at hand.

With a little patience and practice, you’ll be turning out beautifully polished stones in no time. Happy polishing!

Simple Ways to Polish Rocks with a Dremel: 12 Steps

Polishing rocks is just one of the many ways you can use a Dremel rotary tool. Clean off the rocks you want to polish with soap and WikiHow

How to Cut,Shape & Polish Rocks With a Dremel (Step

How to Cut,Shape & Polish Rocks With a Dremel (Step By Step) We are gonna dive into a step-by-step guide on how to cut, then shape, then polish your rocks and stones. Hello Practical!

How to Polish Rocks with a Dremel – YouTube

Learn how to polish rocks with a dremel with this guide from wikiHow: https://www.wikihow.com/Polish-Rocks-with-a-DremelFollow our social media channels to f… YouTube

How To Polish Rocks With A Dremel – Rockhounding Maps

The polishing process is the same, but here are a few things to keep in mind when using a Dremel to polish stones. Choose a Dremel with a low RPM for rock Rockhounding Maps

6 Easy Steps to Polish Gemstones with a Dremel

We’re going to take you through everything you need to know about how to polish gemstones with a Dremel. And by the time we’ve finished, you’ll be ready to start polishing with confidence! So step this Something Borrowed

How to Polish Stones with a Dremel (Rotary Tool) and

How to polish stones with a Rotary Tool and acid will take you through all the steps neccessary to achieve a nice waxy lustre on rootbeer banded calcite. Tip… YouTube

How to Polish Gemstones (Using a Dremel, Tumbler,

There are several ways to polish gemstones at home. But today, we will consider the top three methods: using sandpaper, a Dremel, and a rock tumbler. Let’s get started! All Things Jewelry

How to Use a Dremel to Buff & Polish Stones | Hunker

You can buff and polish stones by hand-using a Dremel tool. In order to buff stones you will need to sand them with several different sandpaper grits as well as buff and polish them with a polishing wheel. The process is labor Hunker

Dremel Polishing Kit: How to Polish Rocks Perfectly

How to Polish Rocks with a Dremel – This video by Jason Woolman provides a great overview of the polishing process using a Dremel rotary tool. He polishes an agate slice and does a wonderful job Polishing expert

How To Polish Rocks With A Dremel

Shaping And Polishing A Rock By Hand With A Dremel Tool!

How To Polish Stones With A Dremel (Rotary Tool) And Acid

How To Polish Rocks With A Dremel | A Guide Featuring Banded Calcite

Dremel Rock Polishing

Dremel Rock Polishing | Fluorite

Experiment In Polishing A Petoskey Stone Using A Dremel Tool

Link to this article: how to polish stones with a dremel.

See more articles in the same category here: https://linksofstrathaven.com/how