Let’s discuss the question: how to grind inside corner welds. We summarize all relevant answers in section Q&A of website Linksofstrathaven.com in category: Blog Finance. See more related questions in the comments below.

Can you grind down welds?

Initial weld grinding. The first stage of weld finishing is the same; the removal of excess stock from the weld itself. The aim here is to grind the joint down to a level and continuous surface with the rest of the parent metal.

Can you weld over a bad weld?

“Can you weld over an existing weld?” Sure you can weld over an existing weld. Unless you can’t weld to begin with because then you may struggle. Another hindrance would be if you forgot to pay the electric bill or if you didn’t have a proper ground.

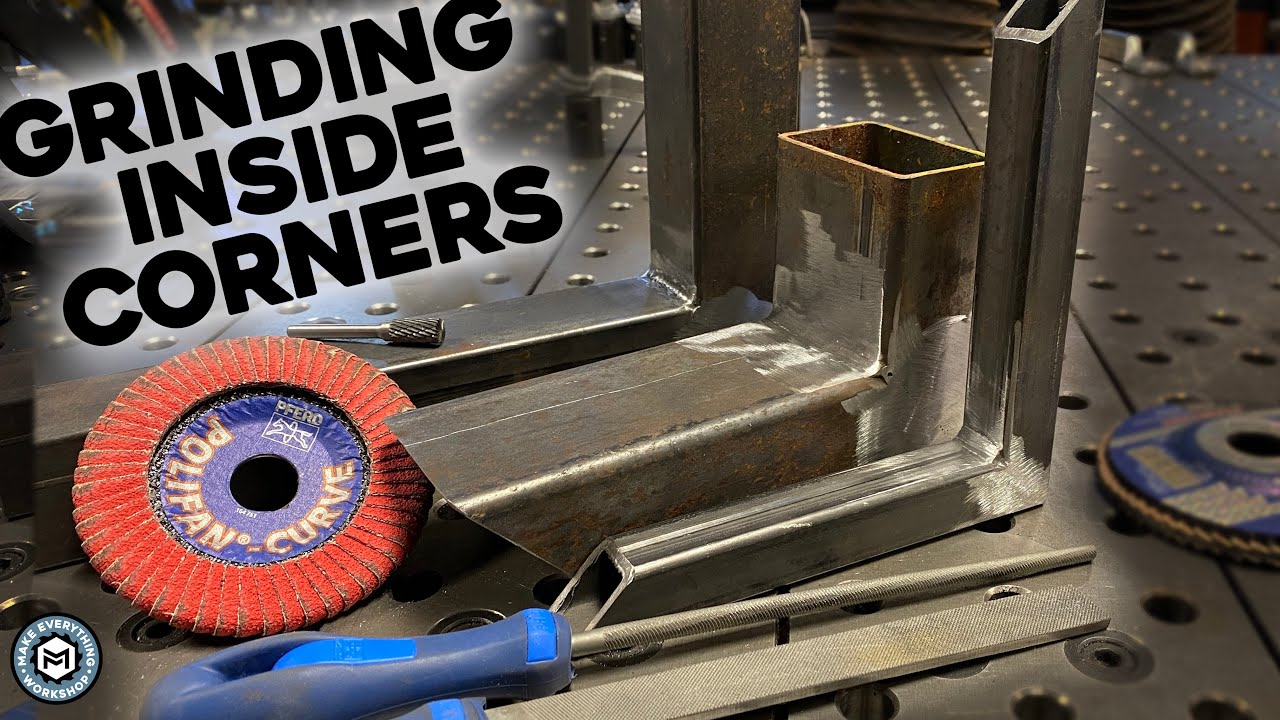

How to Grind Inside Corners – Welding \u0026 Furniture Making

Images related to the topicHow to Grind Inside Corners – Welding \u0026 Furniture Making

Why are my welds flat?

Adjust the parameters to a lower setting so the weld pool is less fluid and more able to fill in the joint. If a concave weld bead appears in the flat or horizontal position, it’s often the result of voltage that’s too high, wire feed speed that is too slow or travel speed that is too fast.

What is grind flush?

Flush-grinding of a butt weld is an established method for improving its fatigue performance. This eliminates the stress concentration created by the weld profile and removes the inherent weld toe flaws at which fatigue cracks typically initiate.

How do you smooth out grinded metal?

Sand the part with progressively finer sandpaper, working from 40-grit down to 320-grit. Once finished with 320-grit sandpaper, the grind marks should be completely removed. If a polished surface is desired use 600-grit sandpaper and water to remove the very fine scratches left by the 320-grit.

Can you grind down metal with a Dremel?

Dremel’s grinding and sharpening tools help you with both activities, whether you’re deburring metal after cutting it, smoothing welded joints or sharpening secateurs. You can use these tools on glass, ceramics, stone and porcelain too.

Blending Welds on Inside Corners

Images related to the topicBlending Welds on Inside Corners

How do you clean a weld?

Wire brushes and wheels are a good option for interpass or post-weld cleaning, when it is necessary to remove spatter and other contaminants. If the material has a lot of mill scale, rust or heat discoloration to remove (without removing a lot of material), wire brushes also work well for pre-cleaning.

Why are my welds cracking?

Cracking can be caused by many different problems from rapid cooling to contamination. But in almost all cases, the reason cracking occurs is because the internal stresses exceed either your weld, your base metal or both. After you weld, both your base metal and your weld begin shirking as they cool.

Should you weld both sides?

When you can weld from both sides of the joint, a full-penetration weld is easier to accomplish. For thin material, the edges can be butted together, a weld made on one side, and a weld made on the back side that fully penetrates into the first.

How do I know if my weld is strong?

To really test a weld you need to do a x-ray test, magnaflux test, dye penetrant test or ultrasonic test which looks for voids, lack of fusion, etc.

Why do my welds look like popcorn?

A weld may look like popcorn when the wire is speeding too fast or slow or when the fire feeding happens before the melting. If you use solid wire without shielding gas, you might also hear popping sounds. Other reasons may include the wire’s incorrect size, amperage adjustments and voltage.

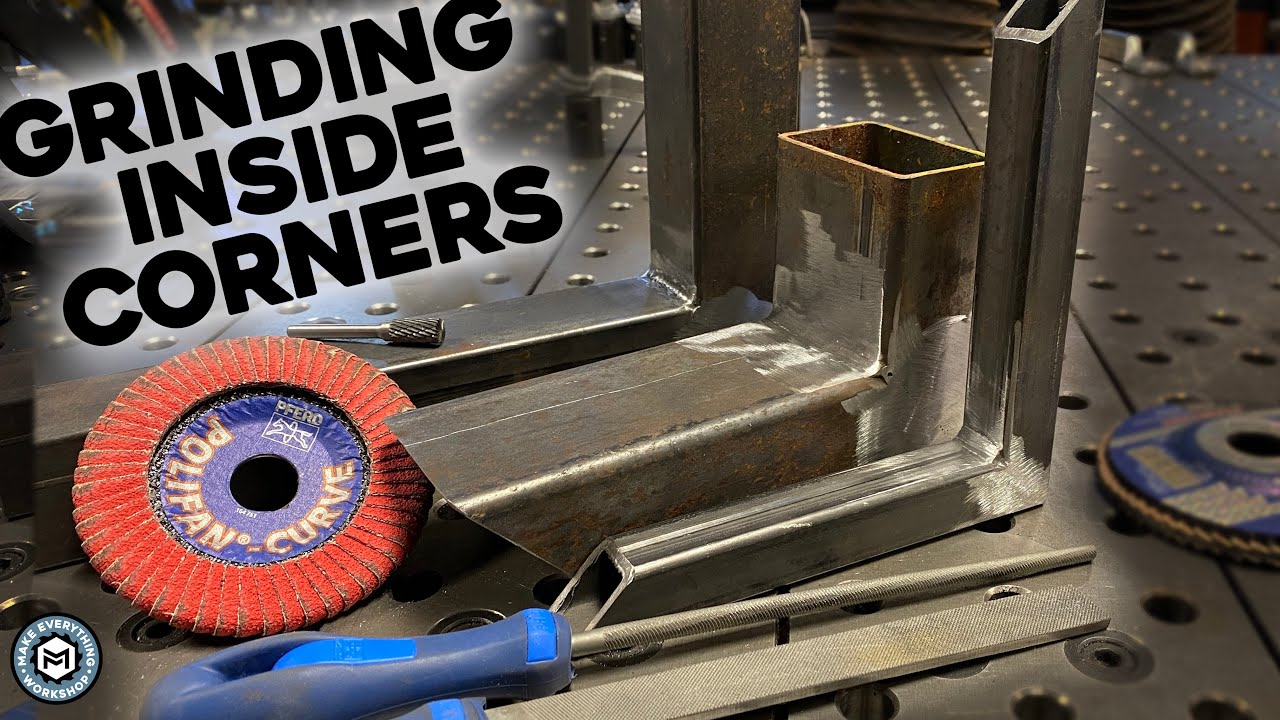

square tube – fillet weld grinding

Images related to the topicsquare tube – fillet weld grinding

How do you get smooth welds?

- Clean, Clean, Clean. …

- Get a Great Ground. …

- Keep Your Stickout Short. …

- Use Both Hands. …

- Listen To Your Welder. …

- Keep The Arc Up Front. …

- Match Drive Rolls, Gun Cable Liner, Contact Tip to the Wire Size. …

- Push or Pull.

What is the ideal welding position for welding?

…

Flat Position Welding Procedures.

| Plate thickness, in. | Number of passes |

|---|---|

| 5/8 to 7/8 | 3 |

| 7/8 to 1-1/8 | 4 |

Related searches

- dremel weld grinding

- sanding down welds

- best way to grind corner welds

- blending fillet welds

- fastest way to grind welds

- how to grind welds in tight corners

- flap disc for grinding welds

- fillet weld grinder

- how to cut a weld in a corner

- what is blending a weld

Information related to the topic how to grind inside corner welds

Here are the search results of the thread how to grind inside corner welds from Bing. You can read more if you want.

You have just come across an article on the topic how to grind inside corner welds. If you found this article useful, please share it. Thank you very much.