Let’s discuss the question: how to build a lightbox for screen printing. We summarize all relevant answers in section Q&A of website Linksofstrathaven.com in category: Blog Finance. See more related questions in the comments below.

Do you need an exposure unit for screen printing?

UV Exposure Unit Equipment Review

UV Exposure Unit Equipment is indispensable equipment for screen printers to make the original design on the printing plate.

What light is needed for screen printing?

The ideal light for screen exposures is one that is rich in ultra-violet (UV) light. Fluorescent, halogen lights and most LED lights are low in ultra-violet (UV) light. But they have a low purchase price and are readily available. This is why most low cost exposure units have them as a light source.

STEP BY STEP EXPOSURE UNIT for SUPER CHEAP [Screen Printing Tutorial] T-shirt Business

Images related to the topicSTEP BY STEP EXPOSURE UNIT for SUPER CHEAP [Screen Printing Tutorial] T-shirt Business

![Step By Step Exposure Unit For Super Cheap [Screen Printing Tutorial] T-Shirt Business](https://i.ytimg.com/vi/bCYr-KNRjBs/maxresdefault.jpg)

What type of screen is used for screen printing?

There are two low-count mesh standards that are used in screen printing shops: 30 to 61 mesh and 80 to 86 mesh. These low-count screens are ideal for simple text, big logos, and other images that don’t really require much detail. Low mesh screens are best when used with plastisol and thicker inks.

How long does it take to burn a screen for screen printing?

Using clear tape, position and secure your image to the surface of the silk screen. Turn on the 150-watt bulb and burn the screen. Again, check the directions on your emulsion, but a good general guideline is to leave the 150-watt bulb on for between 30 and 45 minutes.

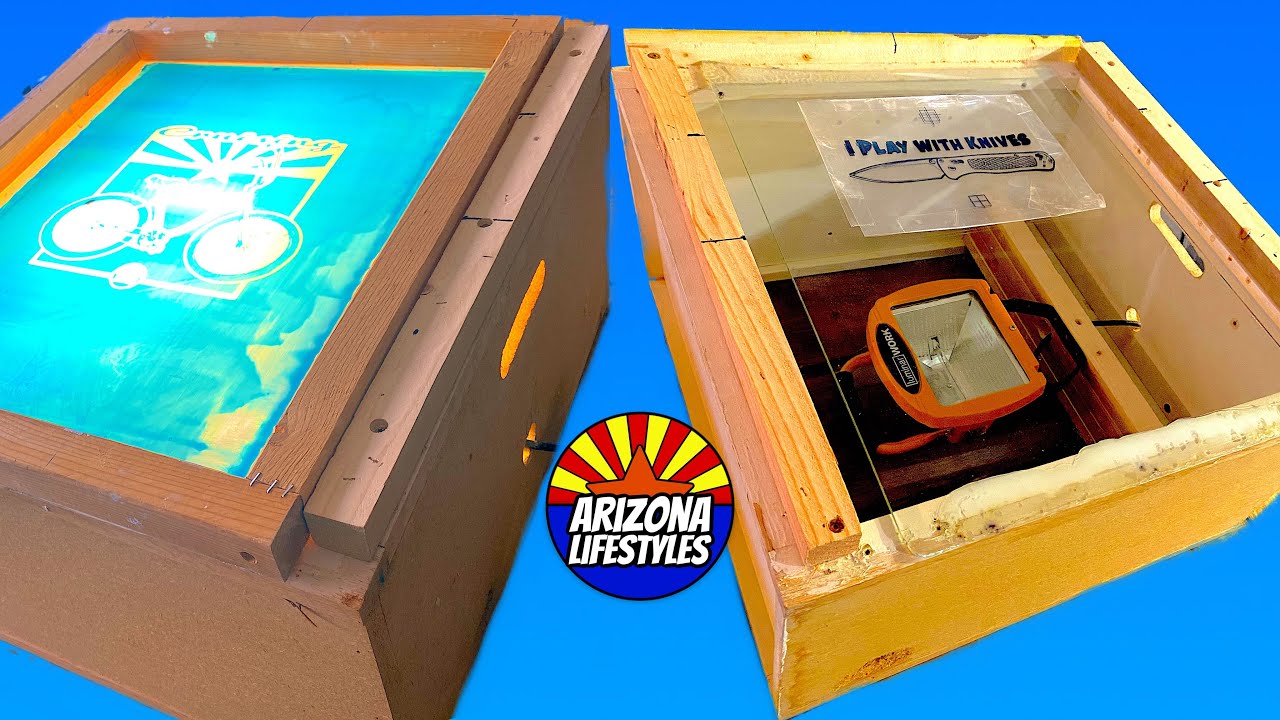

Cheapest DIY Screen Printing Tabletop Exposure Unit and how I made it

Images related to the topicCheapest DIY Screen Printing Tabletop Exposure Unit and how I made it

What watt bulb do you need for screen printing?

A 250-watt bulb or 500 watt halogen light.

What mesh do I need for screen printing?

Generally, mesh counts ranging from 25 mesh to 305 mesh are ideal when screen printing. Mesh count is the number of openings within an inch in any direction. This means a 305 mesh screen is much finer than a 25 mesh screen.

How detailed can you screen print?

The right mesh count for the job

Regarding TITO: The ideal resolution for an image? preferably a vector image over a raster one?to be screen printed is 300 dpi. Again, a professional printer with experience beneath his or her belt can provide satisfying results from just about any start point.

Building A New DIY Exposure Unit /// Screen Printing Halftones

Images related to the topicBuilding A New DIY Exposure Unit /// Screen Printing Halftones

What size screen is best for screen printing?

Therefore you need a lower mesh count with large holes in order for all the particles to pass through properly. Shimmer plastisol inks have finer particles in them so you could probably use an 86 mesh while glitter inks have much larger particles so it would be recommended to use a 40 or 60 mesh screen.

How much does it cost to build a 12×12 screened in porch?

If you’re just screening in a porch as it already stands, Home Advisor reports that the installation can cost around $2,000: “The total costs $3 to $5 per square foot for materials, and $2 per square foot for labor,” for an add-on like this, but “if you want to build a completely new porch with screen, you’ll pay $25 …

Related searches

- how to make a lightbox at home

- screen printing light exposure unit

- uv light box for screen printing

- screen printing exposure unit for sale

- make your own lightbox

- screen printing light

- exposure unit for screen printing

- light box for screen printing

- how to make your own lightbox for photography

- how to make lightbox art

- how to make a uv light box for screen printing

- best exposure unit for screen printing

- screen printing exposing

Information related to the topic how to build a lightbox for screen printing

Here are the search results of the thread how to build a lightbox for screen printing from Bing. You can read more if you want.

You have just come across an article on the topic how to build a lightbox for screen printing. If you found this article useful, please share it. Thank you very much.